Modelcars featuring Exposed Carbon Fibre? – NEXT LEVEL FEATURETTE

What's the matter about carbon fiber?

Carbon is considered one of the materials in automotive construction whose importance will increase in the future. Designers love it in all its variations: Real carbon, partial carbon, carbon foil, in the interior or as add-on parts - the dark material looks noble and sporty at the same time. Engineers are at least as enthusiastic about carbon: it guarantees high strength and rigidity with a low specific weight. For this, however, it has to be produced at great expense.

So it is beautiful and valuable - and that makes carbon the black gold among high-tech materials. In motor sports in particular, every kilogram saved counts; lightweight construction is one of the premises in the development of a racing car. Manufacturers are also increasingly using visible carbon in the model car sector. However, they do not use real carbon, but only imitations to make it look like visible carbon. The best examples are the models from BBR and LCD Models, which are increasingly using imitation carbon.

How is exposed carbon going to be produced?

Visually, components in visible carbon fascinate with the fabric structure so characteristic of this material. The carbon fibres themselves are extremely thin - they are often only a tenth of the diameter of a human hair. The direction in which the carbon fibres are laid is of decisive importance for stability: Because carbon is only extremely stiff in the direction of the fibres. For structural components, the next step is to combine around 50,000 of these individual filaments into so-called fibre bundles (rovings) and wind them up. For visible carbon components, the number is around 3,000!

At Lamborghini, for example, the carbon is cut short and pressed, hence the term Forged Carbon. Ferrari, on the other hand, produces carbon in alternate crossings to create a chessboard-like pattern. The most common method is the classic variant, where the patterns alternately overlap twice to create a diagonal pattern. Visible parts are then covered with a clear lacquer - this way the characteristic structure of the carbon remains visible and the material is protected at the same time. For model vehicle manufacturers, the diagonal pattern is also the most common way to implement it on 1:64 scale vehicles. The Koenigsegg Agera RS Naraya was one of the first pilot projects of Tarmacworks to implement a full carbon chassis in the smallest scale.

Exposed carbon parts are largely made by hand. And this is time-consuming. The production of a single component can take a whole day. Preparation, cutting to size, curing in an autoclave, demoulding, milling trimming, painting - all this takes time. But it also guarantees extremely high quality and exclusivity. Ordinary carbon does not have to be produced in such an elaborate way because the parts are covered with layers of paint at a later stage. Visible carbon must therefore remain absolutely flawless, because any inconsistency is immediately punished.

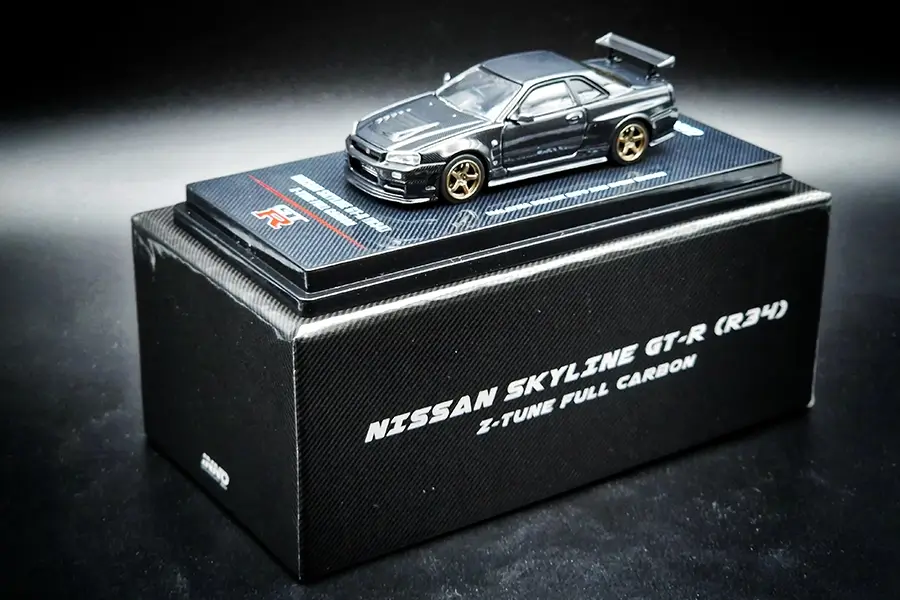

Tarmacworks has clearly stepped up its game with the Pagani Zonda Cinque Black Mamba, which was released at a much later date. Inno64, on the other hand, showed what they are capable of producing in 1/64th scale at the Malaysian Diecast Expo this year in 2023. The Nissan Skyline GTR R34 in full exposed carbon was an absolute highlight and is so far one of the best models Inno64 has ever produced!

What are the advantages of carbon?

Carbon is characterised by many positive properties that set it apart from other materials. One of these advantages is its high rigidity. The structure created by carbon fibres is extremely stable. Carbon can absorb large amounts of impact energy. Used in the right places, carbon therefore helps to increase vehicle safety. Another advantage of carbon is its low specific weight. Body components made of aluminium, one of the most important light metals, can weigh 20 to 30 percent more than a correspondingly used element made of carbon. Less weight also saves fuel. This can be an advantage especially for fuel-hungry sports cars.

Today, sports car and hypercar manufacturers' vehicles are almost exclusively made of carbon. Offering entire chassis made of visible carbon, however, is now a very welcome option for offering customers in the hypercar segment something very exclusive. Symbolic of this is our latest achievement, the Koenigegg Agera One:1 in full exposed carbon. Like the Black Mamba Pagani from Tarmacworks, the engine compartment cover can be removed and is bursting with attention to detail! The TPC One:1 is one of the best models we have ever had the pleasure of holding in our hands in our model car collecting career!

You May Also Like

TPC Apollo IE vs Peako64 DeTomaso P72 FEATURETTE

April 21, 2024

THE WORLD of WATARU KATO – LIBERTYWALK FEATURETTE

January 4, 2024